» In the early 1980's, Fairfield Service Company developed and constructed the screening

equipment for the Mainstream Tunnel System, the CSO pumping project that the Metropolitan

Sanitary District of Greater Chicago (now Metropolitan Water Reclamation District of Grater

Chicago) constructed. The operation was massive compared to conventional headworks

screening: the bar racks were 12' wide x 50' high; the rake traveled to 350' below the operating

floor; the rake weighed 18,000 lbs.; and the hoist drums were driven by two unique (at the time)

VFDs that could go to zero speed and hold a torque.

» In the early 1980's, Fairfield Service Company developed and constructed the screening

equipment for the Mainstream Tunnel System, the CSO pumping project that the Metropolitan

Sanitary District of Greater Chicago (now Metropolitan Water Reclamation District of Grater

Chicago) constructed. The operation was massive compared to conventional headworks

screening: the bar racks were 12' wide x 50' high; the rake traveled to 350' below the operating

floor; the rake weighed 18,000 lbs.; and the hoist drums were driven by two unique (at the time)

VFDs that could go to zero speed and hold a torque.

Fast-forward to 2010:

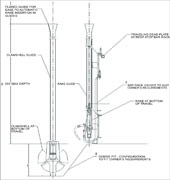

» Unlike some deep-shaft screening systems, the Fairfield Deep Raker removes the debris from the bar rack

while the rake is ascending. The rake grabs while raking, instead of pushing it down towards the invert of the screening

chamber where much debris is not very efficiently removed, as is the case with rakes which clean on the descent.

The rake on the Fairfield Deep Raker is comprised of three elements:

- The Frame

- The Grapple Arm

- The Travelling Dead Plate

Applications

- Cleans on the Ascent

- Uses a Traveling Dead Plate for Debris Capture

- Travels to 350’ Deep

- Uses Vector Motor Control Technology

- Locks The Rake Opened/Closed with a Mechanical Interlock

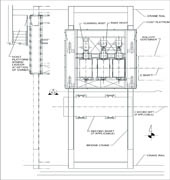

» The hoist system is mounted on a traveling bridge crane and is comprised of two

independently driven drums with a special mechanical interlock system that both locks the two

drives together with the rake (either open or closed), and allows the sharing of loads between

the two drives.

» The hoist system is mounted on a traveling bridge crane and is comprised of two

independently driven drums with a special mechanical interlock system that both locks the two

drives together with the rake (either open or closed), and allows the sharing of loads between

the two drives.

» The bridge crane can be equipped to move in either two or four directions, depending on the

Owner’s specific application, usually dictated by whether there are one or two shafts to be

serviced by the single rake.

» Hoist controls apply 21st Century vector technology to provide outstanding and reliable

position control.

» Depending on the specific customer needs, a clamshell can be provided to clean a

debris pit upstream of the bar rack.

» Stainless steel guides for the system are provided in standard sections to be embedded in

pockets in the side walls of the shaft(s).

Related Product: Trash Rack